Moving beyond Beginner when 3D Printing and becoming a Handy Person

OK, let's just say it. I'm not that handy and I'll never be handy. I'm consistently impressed with all my friends and family members who put up pictures of their amazing dining room tables made from scratch. "Ya, I raised this tree from a sapling, cut it down, and made this table with tools from the 1700s. #diy."

Every time I pick up a saw or a drill I feel like I'm faking it. But I try.

The most important thing when making, I think, is to identify your comfort zone and then push past it a little bit.

I've been doing some 3D Printing lately. In fact I'm being teased by people at work who say the printer is always going whenever they call. I say, if I'm going to make a big purchase like this, it needs to be used all the time or non-technical spouse will tell me that buying it was a mistake.

Here's some of my 3D Printing posts so far:

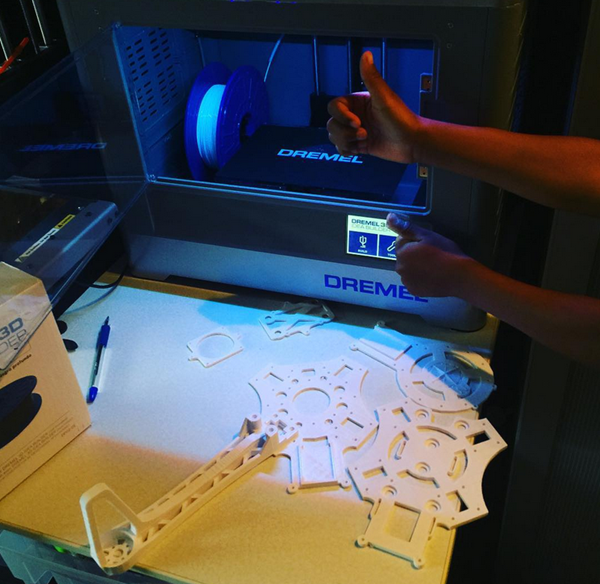

- Review: Dremel 3D Printer and initial impressions of the HP Sprout

- 3D Printer Shootout - $600 Printrbot vs. $20,000 uPrint SE Plus

- Creating exact 3D Models for 3D Printing with JavaScript and OpenJSCAD

- The Basics of 3D Printing in 2015 - from someone with 16 WHOLE HOURS' experience

I'm still a beginner, but I think I'm quickly moving into intermediate skills when printing things on a 3D Printer. Here's some lessons I've learned.

3D Printers are marketed wrong.

Listen up, 3D Printer makers, you're selling these things wrong. I was over at Home Depot recently, it's a lumber/tools/fixit shop here in the states (where Handy People go to cut wood, I guess) and they had a Dremel 3D Printer on the end of the aisle. I have a Dremel, so asked a few questions and pretended to be a new customer. They had setup a bunch of little colorful plastic toys. You've seen these demonstrations, right? It's all the little crap like Yoda heads and stuff. It has its place, but at some point you're like "OK, but what can I make that I can use?"

It's a Home Improvement Store where Handy People go, not a Hobby Shop. Show me stuff I can make that will fix my house!

The first thing I printed was a wall bracket for my Dyson Handheld Vacuum. (Again, the goal here is to have non-technical spouse appreciate that I, too, am a Handy Person.)

3D Printer manufacturers should showcase all the cool utilitarian stuff you can make. Which leads me to...

Material/Filament - There's more than just vanilla PLA and ABS

When you print, you use filament which are spools of plastic spaghetti. There's lots of materials but the first one we all use is PLA, which is a plant-based biodegradable plastic. Later folks move on to ABS Plastic, which is what LEGO bricks are made of. I haven't gotten that far yet and have only printed PLA...however.

There is a company called Proto-Pasta that makes and sells "exotic filaments" including PLAs that include Carbon Fiber, Magnetic Iron, like a Conductive PLA, or High Temp PLA. The High Temp PLA can be head treated (put them in the oven) and they'll then become very heat resistant AND a lot stiffer and stronger.

On the left in this pic is a clear High Temp PLA print of a bracket I wanted. Then I put it in the Oven for 20 min at 230F. The one on the right has crystalized and changed from translucent to opaque and it's VERY STRONG.

I mention this because discovering and using this High Temp PLA opened up a whole world to me. Now I can try printing simple circuit boards with Conductive PLA! The point is, I was playing it safe, but now my possibilities have multiplied.

Software - Way more important than I thought

As I mentioned in my post on The Basics of 3D Printing in 2015 there is a lot of great open source software that you can use to 3D Print with. In fact, you can make your own 3D printer using off the shelf parts and open source design, so there's no real need for you to spend any money on software.

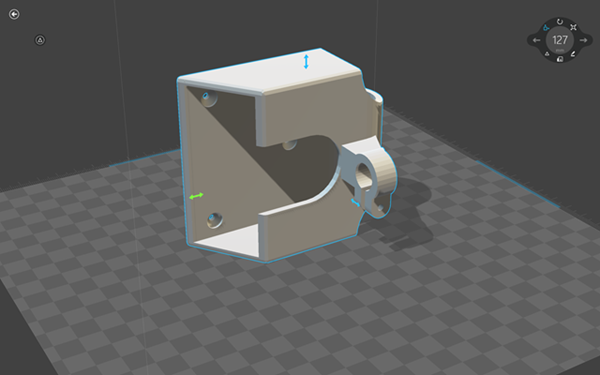

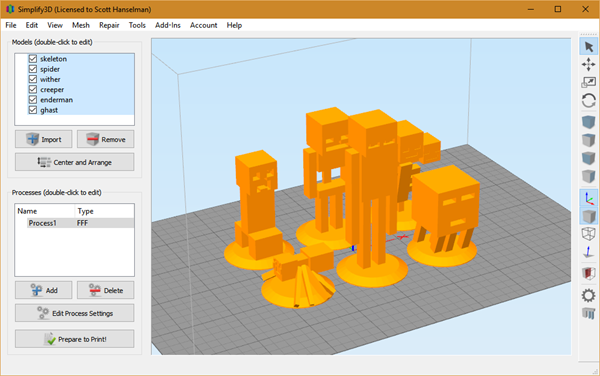

But. I was talking with a 3D Printing expert at a MakerFaire and they gushed about Simplify3D. It's an all in one 3D Printing software that can take in 3D models, arrange them, slice them (slicing means turn the 3D model into x-y-z movements for the printer) and so much more.

Before I was using multiple apps, constantly tinkering, fighting with the built-in software, moving files from app to app in a disjoint workflow. With Simplify3D not only is it easier, but the parts are better. How? It is just that much smarter software, IMHO.

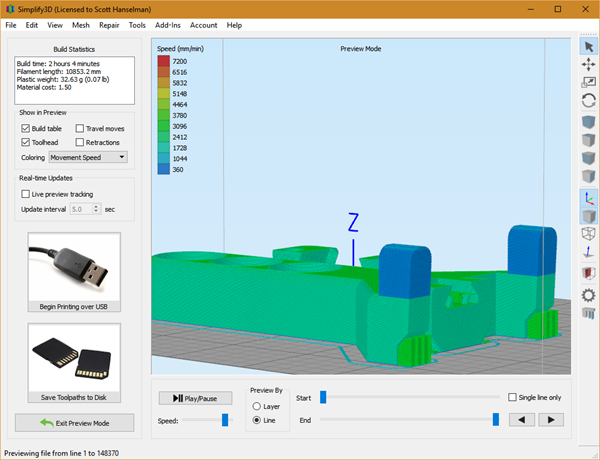

I love this view below. I've got a bracket I'm going to print, and the have colored the "moves" of the print head intelligently showing how many mm per min (mm/min) the print head will move. See how the software is smart about the speed of the supports versus the walls versus the parts that stick up?

Simplify3D made the Minecraft Chess set possible when other systems were creating weird supports or moving too fast and tipping over the fragile parts.

Seriously, if you're moving to intermediate like I am, pay the money and buy Simplify3D. I don't say that lightly. I'm just scratching the surface and learning what it can do, but so far it's already been worth the money. I have no relationship with the company and there's no affiliate code on the link.

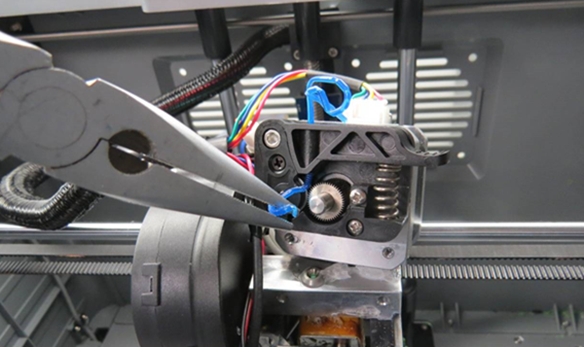

Fear - I was still afraid of the device...until I took it apart

For the most part I've been using my Dremel and Printrbot 3D Printers without issue or incident. However after a few hundred hours of successful printing a snag in the filament spool as it unraveled somehow caused a clog in the Dremel. I was kind of freaking out. 3D Printers are somewhat persnickety and when you have one well-calibrated you don't usually want to mess with it. I thought.

I called Dremel Tech Support and let me tell you, someone give Adrian Malone at Dremel Consumer Services a raise. I called them up and Adrian was in the middle of a print. First, I love that, folks that use their products. He say he had over 1000 hours on that machine (the machines keep track) and he talked my courage up until I felt prepared to take about the whole head and unclog it. His instructions were crystal clear, he was patient and kind. All the things Tech Support should be. Gave me his extension but told me anyone could help...and I have a feeling they could. I've heard tales of Dremel Tech Support being amazing for these printers before this cemented it.

Keep Printing - If you're not using it, you're not learning

My 7 year old and I are printing a quadcopter from places called "CrossFire 2" as a (many) weekend project. We printed a money clip for his allowance last week. We just finished the Minecraft Chess Set today. We're always making, but more importantly, we're always learning. \

Are you 3D Printing? What kinds of stuff do you make? What tips did I miss? Sound off in the comments.

Sponsor: Thanks to my friends at Accusoft for sponsoring the feed this week. Just a few lines of code lets you add HTML5 document viewing, redaction, annotation, and more to your apps and websites.Download a free trial now!

About Scott

Scott Hanselman is a former professor, former Chief Architect in finance, now speaker, consultant, father, diabetic, and Microsoft employee. He is a failed stand-up comic, a cornrower, and a book author.

About Newsletter

Oh, and as a post script, I don't know personally of any handypeople that have made chess sets :)

You were talking about PLAs, and I was just looking at the Micro3D printer, and they have a PLA called Chameleon 3D Ink : to quote their website

<p class="blockquote@cite">Chameleon 3D Ink changes to a rich white color when exposed to a specific temperature. Chameleon 3D Ink comes in 10 variations between 7 colors and 4 temperature modes.</p>

If you ever decide to build a small one check out my designs here T4 Quadcopter Mini 250. The biggest print should be less that 3 hours and the whole thing is held together with cable ties. You still might have to do some "soddering" though :)

As you've said in earlier articles, 3D printing is still in the hobbyist stage and each printer is different. We have a Makerbot Replicator 2 and an Ultimaker 2 Extended here at the library where I work (I got to break in and test out the Ultimaker when it arrive a few months ago. I was printing continuously for a month :) ) and each printer can do things better than the other one or produce slightly different results from the same model. Being aware of the abilities and limitations of your printer allows you design better models and parts or avoid designs that could be an issue.

And this comes back to the idea mentioned in this article of always printing things. You'll never know until you try. And you'll never figure out the details without trying different types of prints.

I don't quite know how to tell you this, but after reading your blog for a long time, I've concluded that you are handy. You have a healthy understanding of you limits, which is important when attempting handiness, because it keeps all the appendages attached to the body.

That said, your article a few years back about the "curvey pipey thing under the sink" is one of my favorite articles anywhere, ever. I encourage my new developers to read it all the time, but it applies to life as a whole. All being handy is, is being able to think about abstractions, and keep a mental list of problems you've seen before and how you solved them. People aren't born knowing how to do these things; it's a learning process. It's really about being willing to learn. All it takes to be handy is willingness to open up the case of your 3D printer, some experience with how simple machines work, and the humility to know when you're over your head and need to ask for help.

We live in a golden age for this, too. Want to fix your 3D printer? Tile your backsplash? Replace the power window regulator in your car? You don't need to find a wizened craftsperson or an ancient shop manual to teach you. (Though those things have an important place, see above statement about exceeding abilities.) You probably just need a quick internet search, where you'll find at least a few other people who've done what you're trying to do and posted a video.

In Amsterdam they are building a 3D printed bridge in the Red Light district.

Pretty cool! :)

https://www.thrillist.com/tech/amsterdam-is-using-robots-to-3d-print-a-bridge-mx3d-bridge-project

Scott, keep printing and having fun with your kids. This is a terrific 21st century hobby and I am glad you are enjoying it.

Comments are closed.

This is when the potential of 3D printing really hit me. He was building things to help his daughter that didn't exist or costed tens of thousands of dollars.